How Modular Display Fits Into Scenic Fabrication

Modular construction plays a central role in our scenic fabrication services. We build frameworks and scenic elements using materials like wood, metal, FRP, and composites to create structures that are easily transported, assembled, and reconfigured. This approach gives clients flexibility while maintaining structural integrity and visual impact.

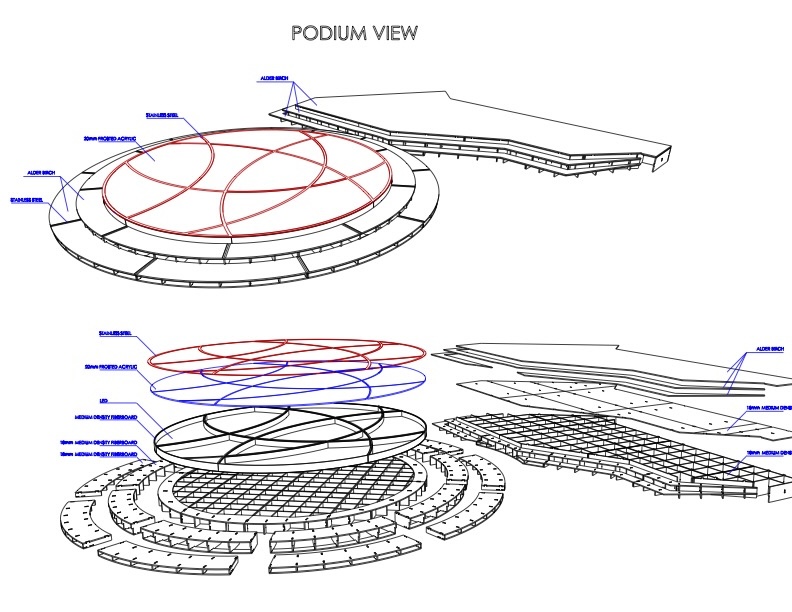

Our technical team develops CAD drawings, exploded views, and production details to make sure each modular component fits together precisely. This level of preparation is essential in modular systems, where efficiency on-site depends on accuracy in the shop. Once fabrication begins, our team works to produce clean edges, exact joints, and finishes that align with the overall scenic vision.

By engineering modular elements in-house, we maintain complete control over quality, schedule, and integration with other scenic components. The result is a modular display that’s reliable in the field and visually cohesive in any setting.

Advantages of Modular Display Systems

Clients turn to modular systems for clear practical reasons. Here are a few of the most important advantages:

Fast Installation and Breakdown

Modular structures are fabricated in our facility and shipped in manageable sections. On-site, crews can assemble these pieces quickly using built-in alignment points and hardware, which helps meet tight installation schedules. This approach also follows industry safety standards for stable scenic construction.

Reuse and Adaptability

With a modular approach, scenic pieces can be reused for future exhibits, events, or seasonal installations. Components can be rearranged or expanded as needed, extending their life cycle and saving time on new builds.

Consistency Across Projects

Because modules are fabricated using detailed technical drawings, each unit connects cleanly with the next. This precision ensures repeatability, even when projects span multiple locations or seasons.

Integration with Scenic Finishes

Our team combines structural systems with scenic finishes, decorative elements, and integrated lighting. A modular display isn’t just a frame; it’s part of a complete scenic environment.

Real-World Applications

Modular systems show up in many of the environments Alice Scenic Studios supports. Here are some common applications:

Exhibits and Trade Shows

Exhibit booths often need to travel between venues. Modular structures make this easy by allowing the same core framework to be installed in different configurations, maintaining brand consistency while adapting to various floor plans.

Broadcast Studios

Modular scenic elements let production teams swap backgrounds and set sections efficiently, creating fresh looks without building from scratch each time.

Themed Environments

Modular components can replicate scenic elements across different zones in a park, museum, or retail space. This provides design consistency while keeping installation timelines under control.

Seasonal Decor

Holiday and seasonal installations benefit from modular construction because large decorative elements can be stored and reassembled each year without needing full rebuilds.

Our Process: Engineering Modular Display Through Custom Fabrication

All projects follow a structured process to keep fabrication accurate and installation smooth. Custom Fabrication is at the heart of this workflow:

1. Concept and Planning

Our production and technical teams review client-provided concepts to identify where modular structures make the most sense. Early planning ensures that scenic goals align with practical installation requirements.

2. Technical Drawings

We prepare CAD models, exploded views, and detailed shop drawings that define every connection, joint, and surface. This documentation guides fabrication and minimizes surprises later.

3. Fabrication

In our overseas facility, metal, wood, and composite materials are cut, shaped, and finished to match technical drawings. Precision at this stage is what makes modular systems reliable in the field.

4. Finishing and Detailing

Modules are painted, textured, or finished to meet scenic goals. This step integrates the structural system with the decorative vision.

5. Installation and Storage

On-site, crews assemble the modules using built-in connections. After use, the components can be disassembled and stored for future projects, extending their usefulness and saving costs over time.

Why Choose Alice Scenic Studios for Modular Display

Clients choose Alice Scenic Studios for modular systems because we handle the entire process under one roof. Our integrated workflow combines technical planning, custom fabrication, finishing, and installation, ensuring every component aligns perfectly with the scenic vision.

With U.S.-based project management and overseas production, we provide high-quality scenic fabrication at a competitive scale. Our portfolio spans museums, theme parks, retail spaces, broadcast studios, and holiday installations — all environments where modular strategies keep projects efficient and consistent.

Bring Modular Display to Your Next Project

A modular display is more than a structure; it’s a practical, engineered solution that supports creativity while keeping projects on schedule. Alice Scenic Studios builds modular systems that are precise, reusable, and designed to integrate seamlessly with larger scenic environments. To get started on your next project, contact us today.