Precision in Custom Stainless Steel Fabrication for Scenic Environments

At Alice Scenic Studios, we approach every project with creativity, technical know-how, and hands-on craftsmanship. One of the materials that plays a key role in many of our builds is stainless steel. It’s strong, reliable, and ideal for both structural and decorative elements. If you’ve been searching for custom stainless steel fabrication near me, our team brings years of experience producing components for museums, themed spaces, and architectural installations that demand a polished, long-lasting finish.

How Stainless Steel Fits Into Scenic Fabrication

Our scenic fabrication services cover everything from woodwork and composites to intricate metal structures. Stainless steel fits seamlessly into this process. It’s often used to build frameworks, decorative details, and architectural accents that need to look refined while standing up to real-world conditions.

In our shop, stainless steel components are cut, shaped, and finished with precision so they integrate smoothly with other materials like wood, FRP, and molded decorative elements. This approach lets us create large scenic pieces that are both sturdy and visually striking, without depending on external suppliers. Each piece is built in-house, which gives us full control over quality and timing.

Our technical team backs this up with detailed planning. Using CAD models, elevations, and production drawings, they map out every joint, bracket, and connection point. That preparation ensures stainless steel structures fit exactly as designed once they’re on site.

Key Advantages of Stainless Steel Fabrication

Choosing stainless steel brings clear benefits for scenic and architectural work. Here are a few reasons it’s often the material of choice for our projects:

1. Corrosion Resistance

Stainless steel can handle many different environments, making it suitable for both indoor and outdoor use. Museum installations, decorative railings, and exterior elements all benefit from its ability to resist moisture and maintain its finish over time.

2. Durability and Strength

For structural pieces, stainless steel delivers dependable strength without excessive weight. It’s often used in supporting frames, mounting hardware, or sections that need to hold their shape for years under regular use.

3. Refined Finish

The polished look of stainless steel is ideal for visible architectural details. It pairs well with other scenic finishes, allowing us to create a clean, contemporary aesthetic that elevates the overall environment.

4. Consistency and Precision

Because stainless steel is easy to machine and weld accurately, we can fabricate components that match digital plans exactly. This level of precision is essential for modular scenic systems, exhibit frames, and decorative assemblies.

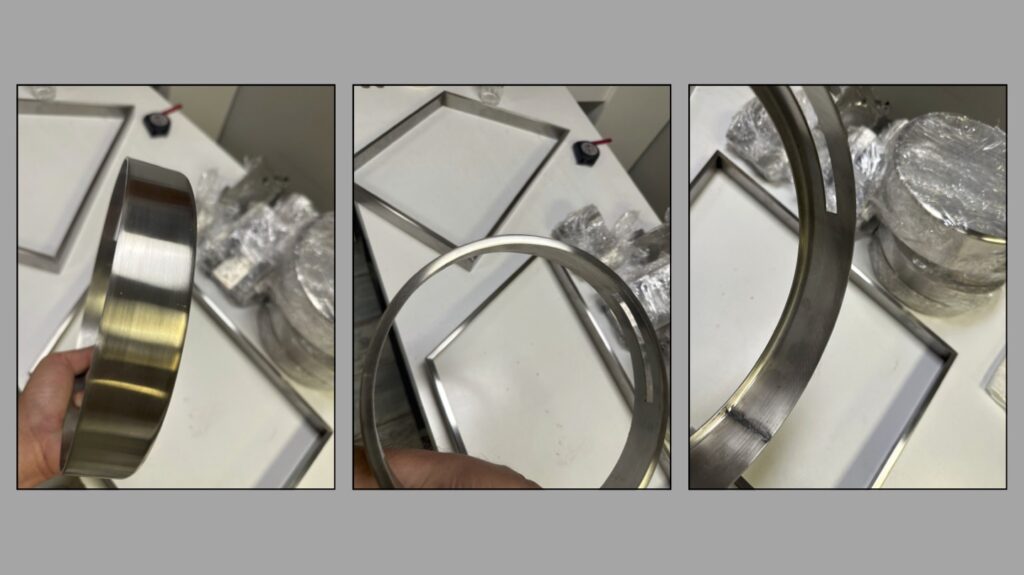

Case Study: Stainless Steel Components for a Museum Exhibit

A recent project for a museum highlights how stainless steel fits into our work. Our team fabricated rings, brackets, and framing elements from stainless steel, each cut and welded to exact measurements. These pieces served both as structural supports and as decorative architectural accents within the exhibit.

The polished finish gave the installation a refined look, while the material’s strength ensured stability over time. By handling the entire process internally — from design through to installation — we delivered a finished result that met tight deadlines and maintained the level of craftsmanship clients expect from Alice Scenic Studios.

Our Process for Stainless Steel Fabrication

Each stainless steel project follows a well-defined process that blends creativity with technical precision:

Concept and Design Review

Every project begins with collaboration between designers, fabricators, and technical specialists. Together, we determine how stainless steel will be used structurally and decoratively, then map out the material approach.

Technical Drawings and Modeling

Our technical team produces detailed CAD drawings, exploded views, and shop documents that outline every dimension and connection. This ensures clarity before fabrication begins.

Fabrication and Finishing

In our metalwork facility, stainless steel is cut, bent, and welded to spec. Each piece is finished to achieve the right surface quality, whether it’s a polished edge or a smooth, brushed texture.

Quality Control and Packing

Every part is checked for accuracy before leaving the shop. We plan for shipping and installation carefully, making sure pieces arrive ready to fit together on site.

Installation and Integration

On-site crews assemble the components, working alongside carpentry, scenic, and AV teams. This coordinated approach keeps projects moving smoothly and maintains the design vision through to completion.

Why Choose Alice Scenic Studios for Custom Stainless Steel Fabrication Near Me

Clients turn to Alice Scenic Studios because we bring every piece of the process under one roof. Our team handles design, technical documentation, fabrication, finishing, and installation in-house. That integration ensures that stainless steel elements line up perfectly with the scenic environment, avoiding the issues that can come with outsourcing.

With project management based in the U.S. and production carried out in our overseas facility, we combine close communication with efficient fabrication. This model allows us to deliver high-quality stainless steel components at competitive prices for large-scale projects across the country.

Our portfolio includes work for theme parks, museums, studios, and seasonal installations, all of which rely on precise metalwork as part of their scenic environments. By focusing on stainless steel, we provide solutions that last, look refined, and fit complex technical demands.

Bring Stainless Steel Craftsmanship to Your Next Project

For designers, architects, and production teams looking for custom stainless steel fabrication near me, Alice Scenic Studios offers the expertise and infrastructure to bring ideas to life. From museum exhibits to decorative architectural installations, we build stainless steel components that combine strength, precision, and visual impact.

If your next project calls for scenic elements that are built to last, our team is ready to help from concept through to installation.